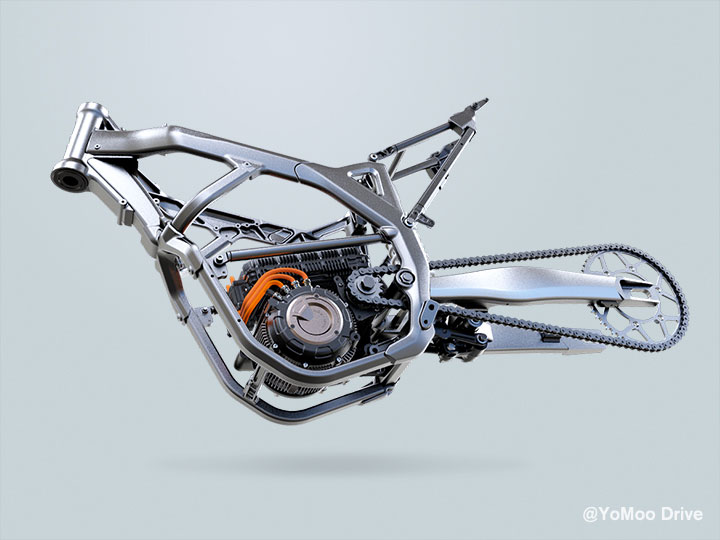

Forging Frame for Electric Dirt Bike

Forging frame was a good choice for high end vehicle design, which offered very light weight, excellent appearance and high strength, especially for off-road vehicles like electric dirt bike, which used in jumping and falling scenarios.

Advantages of forging frame

Forging is a manufacturing process by which metal is pressed under great pressure into high strength desired parts. The process is normally (but not always) performed hot by preheating the metal to a desired temperature before it is worked. It’s important to note that the forging process is entirely different from the casting process (forging vs casting), as metal used to make forged parts is never melted and poured as operated in the casting process. Forging refines the grain structure and improves the physical properties of the metal, so that the grain flow can be oriented in the direction of principal stresses encountered in actual use. Physical properties such as strength, ductility, and toughness are much better in a forging than in the base metal.